|

|

|

#1 |

|

Member

Join Date: Jul 2009

Posts: 611

|

If I didn't know any better, I'd think this came from an S&M club.

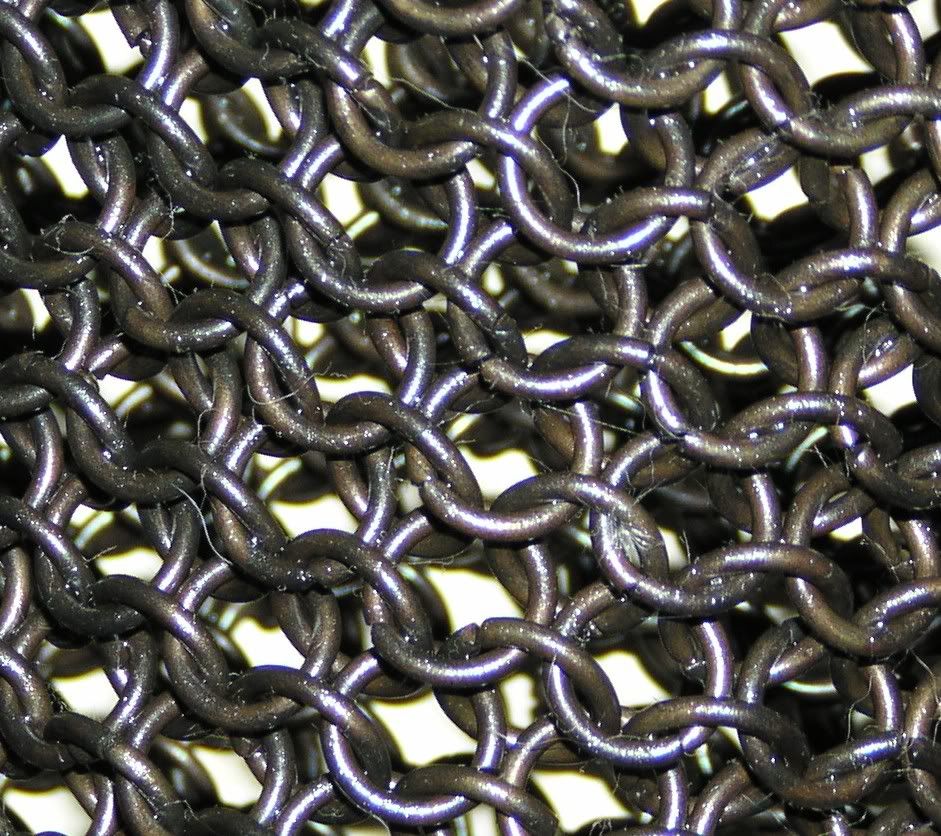

Size is roughly 100 cm wide x 50 cm long, more a t-shirt, than a shirt proper; rather heavy at about 7 lbs. Rings are about 6 mm in outer diameter, and are not riveted, which perhaps indicates that this piece being indo-persian, but I am not sure.. Thanks in advance.

|

|

|

|

|

|

#2 |

|

Member

Join Date: Jul 2009

Posts: 611

|

BTW, my intention is to sell this piece, which obviously doesn't indicate that this is an advertisement of an item for sale. I just want to know the origin of it, and the books I have are not of much help in this instance. If this doesn't sit well with someone here [i.e. 'why should I bother helping someone who's going to profit', etc. etc], then you might want to abstain.

|

|

|

|

|

|

#3 | |

|

Arms Historian

Join Date: Dec 2004

Location: Route 66

Posts: 10,791

|

Quote:

I dont know much on this topic and I'm always up for learning. I dont know much on this topic and I'm always up for learning. Since this is a topic that pertains to possible sale of an item, it is good to note, as I'm sure you already have, that the information shared by members in the discussion is referred to in the rules posted. All the best, Jim Last edited by Jim McDougall; 27th July 2009 at 07:51 AM. |

|

|

|

|

|

|

#4 |

|

Member

Join Date: Jun 2008

Location: The Sharp end

Posts: 2,928

|

Hi Dmitry

When looking at mail I always look at a few things. Firstly initial 'look'. Which in the case of yours makes me wonder why there is no corrosion at all. So, the weight means it must be steel, so is it galvanised/zinc coated? If not then why doesn't it have some rusty patches? Second the construction. Its simple butted links. Have a close look, are they all round and the same size, are they all closed perfectly? Thirdly, try bending one near the edge of the shirt and see if it resists being opened like its heat treated/tempered in some way or just bends. I wouldn't want to make a guess until I know these things. In any event a good looking shirt! Regards Gene |

|

|

|

|

|

#5 | |

|

Arms Historian

Join Date: Dec 2004

Location: Route 66

Posts: 10,791

|

Quote:

Well observed and very nicely put Gene!! |

|

|

|

|

|

|

#6 | |

|

Member

Join Date: Sep 2008

Location: PR, USA

Posts: 679

|

Hi Guys,

Once again, I have absolutely no problem if any info that I may provide is used by a forum member to help sell his article. OTOH, I want to be very clear that my collection is in a continuous state of flux, and that any of the items I discuss here may be sold/exchanged at any moment, although they are not for sale at the time of the discussion. Sometimes, after I find out the provenance of an item, the fun is simply over. Gene, is good to see we have members knowledgeable in so many fields. Good observations! We live to learn. Dmitri, I posted a russian sword for you some weeks ago, did you get to see it..? Guys, regarding my collection, I'm not a "dealer", but to be utterly frank, with very few exceptions, if I'm offered oodles of moollah for something it _will_ be sold! (Then I'll use that the money buy other toys..: ) Isn't that the name of the game? BTW: Anyone care to buy a mother-in-law..? Best Manolo Quote:

Last edited by celtan; 29th July 2009 at 03:58 PM. |

|

|

|

|

|

|

#7 | |

|

(deceased)

Join Date: Dec 2004

Location: Portugal

Posts: 9,694

|

Hola Manolete

Quote:

. .Saludos Nando |

|

|

|

|

|

|

#8 | |

|

(deceased)

Join Date: Dec 2004

Location: Portugal

Posts: 9,694

|

Hi Jim,

Out in the prarie? Quote:

To be or not to be ... genuinely aged; that's the question. Fernando Last edited by fernando; 29th July 2009 at 05:01 PM. |

|

|

|

|

|

|

#9 |

|

Member

Join Date: Jun 2008

Location: The Sharp end

Posts: 2,928

|

Jim,

You are as always very kind. Thank you buddy.  Manolo, Thanks  A tiny amount of knowledge on a wide range of subjects often gets me into trouble A tiny amount of knowledge on a wide range of subjects often gets me into trouble  I have very similar thoughts about my collection. It's quite small and ecclectic by the standards of many here, and whilst I have many pieces that I would wish to keep permenantly, I'm a man of modest means with diverse taste who cant resist a bargain! This often means I buy items, clean them up, identify them (sometimes by asking here), sometimes I need to rebuild and restore them, then I enjoy them for a while, but if I wish to be able to acquire more, I need to sell or swap them to make room/fund others. Its how I learn, how I get to keep some of my favourite things, and how I aspire to own others. As to Dmitry's Chainmail, if there is any ambiguity with chainmail I always think about the materials technique and construction. Dmitry's items are the classic simple form of linking, medium sized butted links etc. I would be thinking about where the links came from, were they produced as links or made from steel wire. From his picture I cant see any flattenning or 'shaping' of the links. I'm sure we all already have opinions on this set, hopefully Dmitry will rejoin the discussion and we can solve the question completely. Regards Gene |

|

|

|

|

|

#10 |

|

Arms Historian

Join Date: Dec 2004

Location: Route 66

Posts: 10,791

|

Interesting comments overall, and Nando, you are truly an 'artiste' with words...crescendo, very well put!

I think with collectors, most collections are in varying degree 'in flux', and often pieces have to be 'let go' either to upgrade or as interests digress into other fields. Most individuals must make these choices as typically, most of us do not have the means to acquire items as comprehensively as we would like to. Many become dealers in degree as well, in order to subsidize thier collecting. With this understanding I think we all agree that buying and selling items is most often a necessary element of collecting.Personally I admire sellers who responsibly try to learn all they can about an item before placing it for sale, and present the description as accurately and detailed as possible. Returning to the subject at hand, the identification of this chainmail, I will say again that the comments thus far seem to well address the condition of the mail, and I look forward to hearing more on the construction, as Gene has well noted. It seems I have studied arms and armour most of my life, and the more I think I know, the more I realize how much I dont know  I love to learn and being here in these discussions is by far the greatest joy ever, where the learning never stops. I love to learn and being here in these discussions is by far the greatest joy ever, where the learning never stops. Perhaps some close up shots will give better look at the construction Dmitry. Nando, you got it, on the prairie as always it seems, headed west toward El Paso, on the 'low road' (US 10) long drive to Tuscon, then in for 'wagon repairs' then northern Arizona near Flagstaff. The 'Boss' says I gotta thin out the library some here in the bookmobile or we're gonna need new shocks  All the best, Jim |

|

|

|

|

|

#11 | |||

|

(deceased)

Join Date: Dec 2004

Location: Portugal

Posts: 9,694

|

Hi again Jim cowboy,

Quote:

. .Quote:

Quote:

. .Have a nice ride. Fernando |

|||

|

|

|

|

|

#12 |

|

Member

Join Date: Mar 2006

Location: Room 101, Glos. UK

Posts: 4,278

|

for reference:

maille is normally made by wrapping a steel wire helically around a hard steel mandril, the wire is then cut in a straight line lengthwise across the top of the mandril with a chisel. for butted, the rings are assembled and the slightly offset ends bent back into place. in the example below, the chisel cut ends are apparent. for riveted, the ends are further processed by hammering flat, punching a hole in each flat, then using a small triangular sliver to rivet the ends together. indo-persian armour usually uses round rivets. 19c parade armour is usually butted. Up until the 14th century European mail was made of alternating rows of both riveted rings and solid rings. After that it was almost all made from riveted rings only. Both would have been made using wrought iron. Some later pieces were made of wrought steel with an appreciable carbon content that allowed the piece to be heat treated. Wire for the riveted rings was formed by either of two methods. One was to hammer out wrought iron into plates and cut or slit the plates. These thin pieces were then pulled through a draw-plate repeatedly until the desired diameter was achieved. Waterwheel powered drawing mills are pictured in several period manuscripts. Another method was to simply forge down an iron billet into a rod and then proceed to draw it out into wire. The solid links would have been made by punching from a sheet.[1] modern maille is usually butted, riveted maille is very expensive due to the hand labour involved, while butted maille can be 'knitted' by machine. butted maille is also sometime found with the butt joint welded electrically. maille can be found nowadays in aluminum (much lighter), stainless steel and galvanised steel, all of which, while rust resistant, do not have the proper 'look'. (just for interest, the maille in lord of the rings was plastic rings, except in closeups) Mail armour provided an effective defence against slashing blows by an edged weapon and penetration by thrusting and piercing weapons; in fact The Royal Armoury at Leeds concluded that, "...it is almost impossible to penetrate using any conventional medieval weapon..." A good sword blow, arriving in exactly perpendicular angle to surface, could cut through the links; when the mail was not riveted a well placed thrust from a spear or thin sword could penetrate, and a poleaxe or halberd blow could break through the armour, but generally mail provided excellent protection to the soldier. According to a study of skeletons found in Visby, Sweden, a majority of the skeletons showed wounds on less well protected legs.[1] The flexibility of mail meant that a blow would often injure the wearer, potentially causing serious bruising or fractures, and it was a poor defence against head trauma. Mail-clad warriors typically wore separate rigid, helms over their mail coifs for head protection. Likewise, blunt weapons such as maces could harm the wearer by their impact without penetrating the armour; usually a soft armour, such as gambeson, was worn under the hauberk.[1] my maille hauberk: blowup of sleeve:  11mm outside ring dia. 1.65mm thick steel wire, 4 in 1, black oxide finish, greased against rust. a bit dusty. whole hauberk:  full length sleeves, body length is below the knee. weighs about 17+ kilos. 20,000 links, give or take a few. very flexible size wise, fits my 48" chest over a heavy wool tunic, over cotton undies  some of the other bits that go with the hauberk just for the heck of it...   the hauberk overshadowed by it's modern equivalent kevlar body armour. less coverage, but lighter & a tad more bullet/shrapnel resistant. notes: [1] ref:wiki article on maille. Last edited by kronckew; 29th July 2009 at 10:26 PM. |

|

|

|

|

|

#13 |

|

Arms Historian

Join Date: Dec 2004

Location: Route 66

Posts: 10,791

|

"...the best of mail coats, that covers my heart,

heirloom of Hrethel, and Waylands work, finest of byrnies". -"Beowulf" Since I admittedly know absolutely nothing about mail, I could not resist visiting Oakeshott ("The Archaeology of Weapons") from which this quote was taken, and Robinson ("Oriental Armour"). While not adding anything to the identification here, a note in Oakeshott is interesting on the term 'chain mail'; "...there is no such thing as chain mail or chain armor, any more than there can be such a thing as plate mail", (p.90). Apparantly the chain mail term is yet another term poetically applied in literature of the 18th century in describing arms and armour, and in actuality is best described as a shirt of interlocked rings, or mail (Lat. macula, Fr. mailles=mesh or net). As noted in Oakeshott, since this term has been widely used colloquially in description, it is much easier to continue its use, I just thought it was interesting. From most of what I understand, most Eastern mail, that is Persian, Turkish and Indian, of earlier than the beginning of 19th century was rivetted. The mail produced after that was typically for parade armour, as obviously the rivets would add considerable strength to the mail as a unit. This parade mail was of the 'butted' form. It seems apparant that many mail type armours remained in use for some time, especially in ethnographic regions such as the Sudan. Robinson (p.63) describes these as becoming severely worn out due to means of replacement or competant repairs in the remote regions of the Caucusus and others including the Sudan. This seems puzzling regarding the Sudan as on p.86 he discusses the continued manufacture of mail in the Sudan and Arkell ("The Making of Mail at Omdurman", A.J.Arkell, Kush, Vol.IV, p.83-85, 1956) notes a discussion with a Sudanese ironworker. The old ironworker was able to produce with no difficulty whatsoever a sample shirt and of the 'old cut', but different rings were used that were butted and not rivetted. This would suggest that the old shirts were most likely Ottoman? In another interesting reference in Robinson (p.85) it was noted that during the Mahdist conflicts, there were mail shirts produced in Birmingham for the Khedive's 'Iron Men' in Egypts forces sent against the Mahdi's Ansar. These were apparantly of split rings which were so brittle that when they were struck by Sudanese bullets, they shattered and resulted in atrocious wounds. When the warriors gathered items from the fallen, they took the helmets, but left the shirts. As I gathered information to better understand the nature of mail, how it was constructed and how it might have been maintained as servicable, I could find little on what certainly must have been the dread of every knight and warrior, rust. I found that there was at least some evidence of the use of galvanization in India ("Galvanized Indian Mail", Royal Armouries #5, Bottomley and Stallybraces) but apparantly not in Europe, where zinc was not known as an element until the 17th century. I have not yet read this article, but found the title intriguing. I am puzzled by the note on zinc in Europe also as it is I believe used in production of brass from Roman times. My question is how was rust inhibited on these coats of mail in early times, and how were they kept servicable if they became rusted? All best regards, Jim |

|

|

|

|

|

#14 |

|

Member

Join Date: Mar 2006

Location: Room 101, Glos. UK

Posts: 4,278

|

i recall from somewhere (?) that maille shirts would be put in a barrel with sand and rolled about to clean off rust, they were then oiled. possibly thus varnished with a drying oil that would inhibit rust. i recall olive oil was used by the romans. if used in thin coats, it does dry & form a protective coat.

i also recall reading about the maille used at omdurman being brittle due to age, rust and lack of maintenance. |

|

|

|

|

|

#15 |

|

Member

Join Date: Jun 2008

Location: The Sharp end

Posts: 2,928

|

Jim,

I'm very interested to hear about 'old' galavised mail? Do you have any more information? Is it galvanised in the modern sense? I thought that galvanising was essentially 2nd half 20thC? Well, in any commercial sense. As for rust proofing, well, theres the thing isn't it! A heavy 'coat' will over time wear through movement any thin layer of protection and make patches start to rust again. However, as can be seen on Kronckews coat, you can almost kill two birds with one stone if you 'oil brown' the steel. Oil quenching during heat treatment will also apply a semi-flexible rust resistant coating. I'm not sure how you'd do it with primitive means on such a large coat, you'd have to do it in sections then assemble. Kronckew. Have you been cleaning that with 00 wire wool?  Good points, I would also add that ancient hand made 'wire' and wire produced by machine do look very different. Also, there is butted link 'wire' mail made from commercially produced links. I actually have a small item made from commercial links. I better go find it and show you. I'm beginning to confuse myself here! Back in a bit Gene |

|

|

|

|

|

#16 |

|

Arms Historian

Join Date: Dec 2004

Location: Route 66

Posts: 10,791

|

Kronckew, we crossed posts. Absolutely excellent and informative post describing construction and great photos. Really like the comparison of the kevlar and the mail also.

Thank you for addressing my question on servicing of mail and the use of the sand and oil is interesting, and really gives an interesting perspective on this topic. I found some interesting additional information that concerns much earlier detail on European mail, but might add some insight regardless, in 'Warfare in the Middle Ages", Richard Humble, 1989, p.129-130). Here the author notes that the infection that would be caused by rusty mail fragments and sweaty undergarments would create a septic situation with even wounds which would not normally have proven fatal. He discusses the extraction of a bolt from "...amid a vicious tangle of fractured mail rings which must have created a horrific wound". Also noted was that blunt trauma from direct blows, even when mail remained intact often led to massive and disabling bruising, as the mail still had a certain amount of 'give' that the undergarment could not entirely absorb. Other discussions we have had some time ago pertained to the effects of heat in the wearing of armour as well, and resulted in some pretty interesting perspective. Dmitry, I hope you dont mind the digression into the historical aspects here, as it seemed a great opportunity to learn more about mail, as we work at determining more on te identification of your example. All best regards, Jim Gene, just saw your post....I really only just saw that item on galvanized mail, so would be interested to learn more as well on it. Interesting notes on oil applied during manufacture. I wonder if annealing and applying oil while working the metal rings would have added some minimal protection ? |

|

|

|

|

|

#17 |

|

Member

Join Date: Mar 2006

Location: Room 101, Glos. UK

Posts: 4,278

|

the romans of course, having conquered britain, had access to tin. it was apparently used extensively to tin plate steel and bronze, as well as orichalcum (brass) used in armour, to prevent rust.

The sestertius, a coin worth four asses and dupondius, worth two asses were both struck in orichalcum brass. The as was about the same size as the dupondius but was struck in more or less pure copper, which was much redder than the brass when newly minted. It is surprising to many modern students of history to find out that the Greeks and Romans could control very precisely the percentage of each different metal that went into their alloys. The fineness or proportion of precious metal in an alloy was most important in commerce and archaeological research has shown that the Romans could control the finess of gold in their coins and ingots to within one percent. This degree of control not only allowed the Romans to closely guard the purity of their gold and silver coins but allowed them to cheat accurately as well! An alloy of copper and zinc called orichalcum was used a great deal by the Romans. This consisted of eighty percent copper and twenty percent zinc, with small amounts of lead, tin, and other metals and would be called yellow brass today. [1] p.s. - atlantia, it was not cleaned with wire wool, but the doggies have contributed a lot of hair to the atmosphere here. everything has dog hair on it to some extent.  one adapts... one adapts...p.p.s. - chain mail consists of a message that attempts to induce the recipient to make a number of copies of the message and then pass them on to as many recipients as possible  [1] - found on the interweb.... Last edited by kronckew; 30th July 2009 at 12:09 AM. |

|

|

|

|

|

#18 | |

|

Member

Join Date: Jun 2008

Location: The Sharp end

Posts: 2,928

|

Quote:

here are some mail samples. (sadly none are medieval) Firstly, dating to early 20thC mail, appears to have been hand assembled, but produced from commercialy made 'wire' links. Note the clean cut edges and completely regular sizes each link is 8mm across.  Second Indian mail made from hand made galvanised wire links, each link is approximately 8mm, note the visible irregularities:  third, Indian mail, some age, hand made from wire links, some variation but quite good quality. approx 10mm links, some heat colouring and signs of oil browning.  Lastly, modern stainless steel welded chainmail. State of the art. Larger link (7mm)

|

|

|

|

|

|

|

#19 |

|

Member

Join Date: Jul 2009

Posts: 611

|

Wow! Thanks for all the input, gentlemen!

I should've set the email notification of replies. Will snap some macro photos of the linkage tonight! |

|

|

|

|

|

#20 |

|

Member

Join Date: Jul 2009

Posts: 611

|

|

|

|

|

|

|

|