for reference:

maille is normally made by wrapping a steel wire helically around a hard steel mandril, the wire is then cut in a straight line lengthwise across the top of the mandril with a chisel. for butted, the rings are assembled and the slightly offset ends bent back into place. in the example below, the chisel cut ends are apparent.

for riveted, the ends are further processed by hammering flat, punching a hole in each flat, then using a small triangular sliver to rivet the ends together. indo-persian armour usually uses round rivets. 19c parade armour is usually butted.

Up until the 14th century European mail was made of alternating rows of both riveted rings and solid rings. After that it was almost all made from riveted rings only. Both would have been made using wrought iron. Some later pieces were made of wrought steel with an appreciable carbon content that allowed the piece to be heat treated. Wire for the riveted rings was formed by either of two methods. One was to hammer out wrought iron into plates and cut or slit the plates. These thin pieces were then pulled through a draw-plate repeatedly until the desired diameter was achieved. Waterwheel powered drawing mills are pictured in several period manuscripts. Another method was to simply forge down an iron billet into a rod and then proceed to draw it out into wire. The solid links would have been made by punching from a sheet.[1]

modern maille is usually butted, riveted maille is very expensive due to the hand labour involved, while butted maille can be 'knitted' by machine. butted maille is also sometime found with the butt joint welded electrically. maille can be found nowadays in aluminum (much lighter), stainless steel and galvanised steel, all of which, while rust resistant, do not have the proper 'look'. (just for interest, the maille in lord of the rings was plastic rings, except in closeups)

Mail armour provided an effective defence against slashing blows by an edged weapon and penetration by thrusting and piercing weapons; in fact The Royal Armoury at Leeds concluded that, "...it is almost impossible to penetrate using any conventional medieval weapon..." A good sword blow, arriving in exactly perpendicular angle to surface, could cut through the links; when the mail was not riveted a well placed thrust from a spear or thin sword could penetrate, and a poleaxe or halberd blow could break through the armour, but generally mail provided excellent protection to the soldier. According to a study of skeletons found in Visby, Sweden, a majority of the skeletons showed wounds on less well protected legs.[1]

The flexibility of mail meant that a blow would often injure the wearer, potentially causing serious bruising or fractures, and it was a poor defence against head trauma. Mail-clad warriors typically wore separate rigid, helms over their mail coifs for head protection. Likewise, blunt weapons such as maces could harm the wearer by their impact without penetrating the armour; usually a soft armour, such as gambeson, was worn under the hauberk.[1]

my maille hauberk:

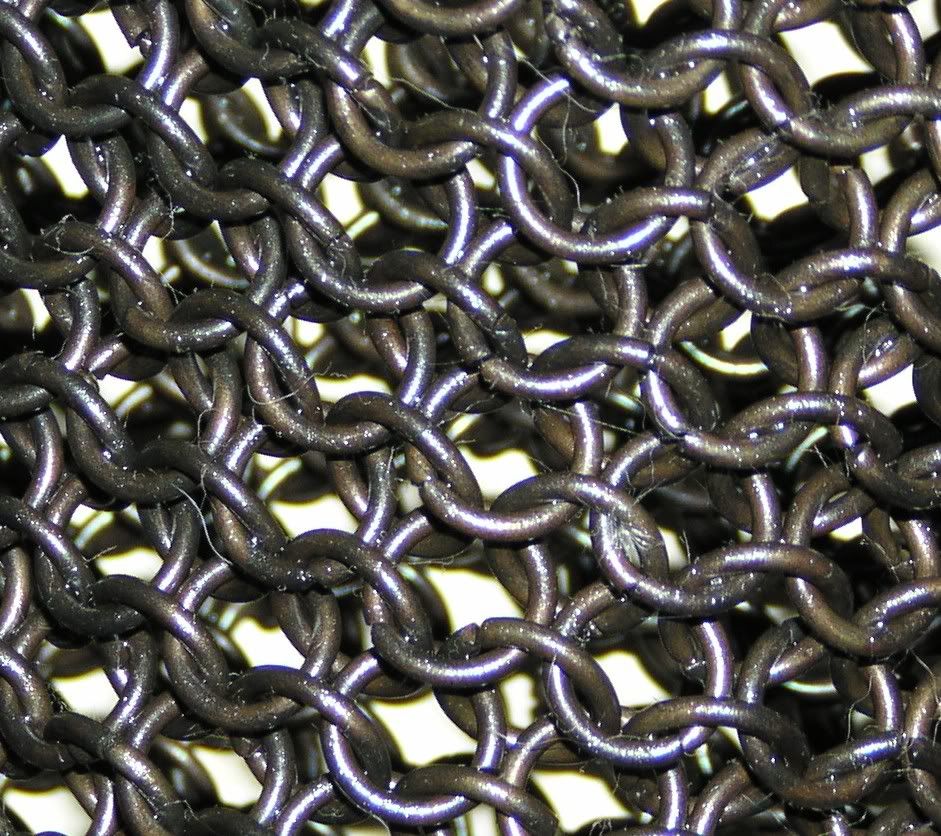

blowup of sleeve:

11mm outside ring dia. 1.65mm thick steel wire, 4 in 1, black oxide finish, greased against rust. a bit dusty.

whole hauberk:

full length sleeves, body length is below the knee.

weighs about 17+ kilos. 20,000 links, give or take a few.

very flexible size wise, fits my 48" chest over a heavy wool tunic, over cotton undies

some of the other bits that go with the hauberk just for the heck of it...

the hauberk overshadowed by it's modern equivalent kevlar body armour.

less coverage, but lighter & a tad more bullet/shrapnel resistant.

notes:

[1] ref:wiki article on maille.